Pre-Stressed Wood Systems

Pre-Stressed Wood Systems

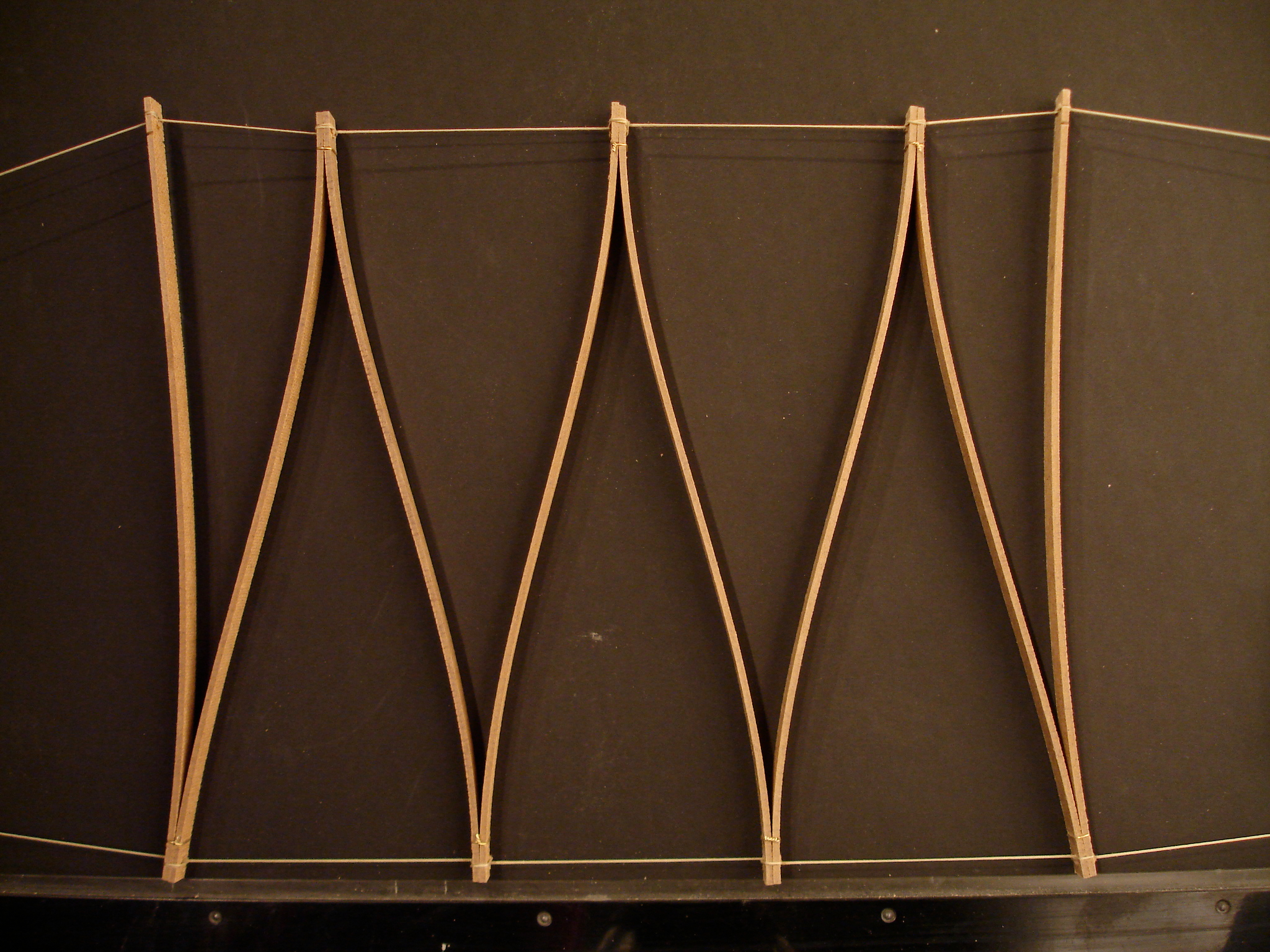

Pre-stressing materials has two main advantages, the first is a form generating result in which the shape of a structure is prepared to receive loading in order to deflect to a desired form; the second is the dramatically increased stiffness and rigidity of the material due to the active stresses it is introduced to. What makes this possible is the flexibility of materials. Most often however, pre-stressing is only used to modify materials with limited flexibility (like concrete) so that the forms resulting from pre-stressing are highly controlled and closely reflecting the form of a non-stressed material.

In these experiments, wood is explored as a material that is able to receive pre-stressed forces, while allowing its high flexibility to create new forms with dynamic and predictable behaviors. The characteristics of the wood (species, grain, quality, dimensions, etc.) contribute to a unique response to the stresses introduced to the structures. The role of the designer in this work shifts from ‘determining’ forms, to ‘negotiating’ form through assembly and the introduction of force. As a result the wood becomes a device for drawing and form finding.

Research Assistant: Dirk Blouw